Ensures the tungsten electrode in the TIG torch is held and kept in position and the shielding gas is distributed sufficiently.

Taurus collets and collet bodies are precision engineered and manufactured from high-quality copper. It ensures that the tungsten electrode in the TIG torch is held and kept in position. The collet body distributes the shielding gas. Once the required tungsten position is established, the back cap can be tightened thereby locking the tungsten in position. This creates a solid contact which is necessary for strong current transfer.

![]()

| PRODUCT CODE | SIZE | TORCH |

| T13N22 | 1.6mm | WP9 |

| T13N23 | 2.4mm | WP9 |

| T10N23 | 1.6mm | WP17 + WP18 + WP26 |

| T10N24 | 2.4mm | WP17 + WP18 + WP26 |

| T10N25 | 3.2mm | WP17 + WP18 + WP26 |

| PRODUCT CODE | SIZE | TORCH |

| T13N27 | 1.6mm | WP9 |

| T13N28 | 2.4mm | WP9 |

| T10N31 | 1.6mm | WP17 + WP18 + WP26 |

| T10N32 | 2.4mm | WP17 + WP18 + WP26 |

| T10N28 | 3.2mm | WP17 + WP18 + WP26 |

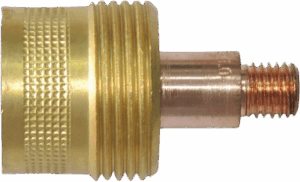

Taurus gas lens collet bodies replace the standard collet bodies enabling increased shielding gas coverage and reduced turbulence. Welding discontinuances associated with atmospheric contaminants are also reduced. Gas lens collet bodies are normally manufactured from a copper-brass alloy and equipped with stainless steel mesh screens. Larger gas lens bodies provide improved gas coverage when materials are welded that tend to react to atmospheric contaminants. On complex joints, larger gas lens bodies also allow greater tungsten stick-out to gain better visibility of the weld puddle or to increase access to the joint. Gas lens collet bodies enable higher quality welds, improved gas flow, lower gas consumption and optimal weld puddle shielding.

| PRODUCT CODE | SIZE | TORCH |

| T45V43 | 1.6mm | WP9 |

| T45V44 | 2.4mm | WP9 |

| T45V25 | 1.6mm | WP17 + WP18 + WP26 |

| T45V26 | 2.4mm | WP17 + WP18 + WP26 |

| T45V27 | 3.2mm | WP17 + WP18 + WP26 |

| PRODUCT CODE | SIZE | TORCH |

| T45V116 | 1.6mm | WP17 + WP18 + WP26 |

| T45V64 | 2.4mm | WP17 + WP18 + WP26 |

Taurus stubby consumables are engineered to shorten the profile of the TIG torch without sacrificing performance. This allows access to more confined welding locations.

| PRODUCT CODE | SIZE | TORCH |

| T10N23S | 1.6mm | WP17 + WP18 + WP26 |

| T10N24S | 2.4mm | WP17 + WP18 + WP26 |

| T10N25S | 3.2mm | WP17 + WP18 + WP26 |

| PRODUCT CODE | SIZE | TORCH |

| T17CB20 | 1.6mm | WP17 + WP18 + WP26 |

| T17CB21 | 2.4mm | WP17 + WP18 + WP26 |

| T17CB22 | 3.2mm | WP17 + WP18 + WP26 |

| PRODUCT CODE | SIZE | TORCH |

| T17GL332 | 2.4mm | WP17 + WP18 + WP26 |